If you’ve ever dealt with uneven airflow, rising utility bills, or an HVAC system that just “doesn’t feel right,” the ECM motor may be part of the story. At Sub Zero Temp Control, we work on blower motors and air handler issues all the time. And honestly? ECM technology is one of the biggest upgrades modern HVAC systems have made in the last couple decades.

However, the big downside is that when an ECM motor acts up, the symptoms can confuse homeowners fast. Sometimes it looks like a thermostat issue. Other times it looks like a capacitor problem. In many cases, it feels like the whole system is dying… when it’s actually one motor component having a rough day.

So let’s break this down clearly.

What Is an ECM Motor?

An ECM motor is an Electronically Commutated Motor. In simple terms, it’s a high-efficiency motor that uses electronics to control speed and torque more precisely than older motor styles.

Unlike traditional blower motors that run at one or a few fixed speeds, ECM motors can:

Ramp up slowly

Adjust speed in small increments

Maintain consistent airflow

Use less electricity

Because of that, they’re common in modern high-efficiency HVAC systems.

Also, they’re typically used as:

Blower motors (in furnaces and air handlers)

Variable-speed indoor fan motors

Motors in systems designed for better comfort and humidity control

And yes—when they fail, they fail in a way that makes techs sigh a little. Not because they’re “bad,” but because troubleshooting can be more involved.

ECM Motors vs PSC Motors (The Older Style)

Before ECM motors became common, most systems used PSC motors (Permanent Split Capacitor motors). PSC motors still exist today, especially in older or builder-grade systems.

Here’s the difference:

PSC motor: simple, less expensive, fixed-speed, higher energy use

ECM motor: electronically controlled, variable-speed, energy efficient

In other words, PSC motors are like a standard light switch. ECM motors are like a dimmer that automatically adjusts.

That matters because airflow isn’t just comfort—it affects:

System efficiency

Coil performance

Humidity removal

Noise levels

Equipment lifespan

Why ECM Motors Are Used in HVAC Systems

We see ECM motors most often in systems where efficiency and comfort matter.

Key Benefits of ECM Motors

Lower electricity use

More consistent airflow

Better temperature control

Better dehumidification

Quieter system operation

Also, ECM motors help prevent the “blast of air” effect when systems start. Instead, they ramp gently, which improves comfort and reduces noise. (Your house shouldn’t sound like it’s taking off every time the system kicks on.)

Common ECM Motor Symptoms Homeowners Notice

ECM motor issues rarely show up as one clean symptom. Instead, they show up as weird behavior.

Here are the most common signs we see:

Weak airflow from vents

Some rooms feel warmer or colder than others

The system runs longer than normal

The blower won’t turn on at all

Fan runs, but airflow is low

You notice higher power bills

Intermittent operation (works sometimes, fails other times)

Also, many homeowners tell us: “It’s running… but it doesn’t feel like it’s doing anything.” That’s a major ECM clue.

ECM Motor Troubleshooting: What Usually Causes Problems?

An ECM motor is part motor, part electronics. Because of that, troubleshooting often involves more than “is it spinning?”

Here are the most common causes behind ECM motor trouble:

Dirty air filter restricting airflow

Overheating due to restricted return vents

Power surges damaging the control module

Loose wiring or failing connectors

A failing motor module (common on some ECM designs)

A control board issue sending the wrong signals

And yes—sometimes the motor is fine, but the system isn’t telling it what to do.

Don’t Ignore Airflow Issues

If airflow is restricted, ECM motors may keep trying to compensate. That strain matters. Over time, it can shorten the motor’s life. For a deeper explanation of why airflow problems and duct losses impact system efficiency, the U.S. Department of Energy explains how duct losses waste energy.

So if you’ve been covering a return air vent, dealing with a dirty air filter, or ignoring duct issues, that can create ECM problems later. And if you’ve ever wondered whether your filter might be part of the problem, the EPA’s breakdown of MERV ratings does a great job explaining how filtration can affect airflow.

How a Run Capacitor Fits Into This (And Why It Matters)

This is where things get confusing.

Some systems use ECM motors with separate components that homeowners mix up with capacitor problems. And in older setups, a failed capacitor can look a lot like a motor failure.

That’s why we often recommend reading our internal guides:

Even if your system uses ECM technology, it’s still helpful to understand how capacitors affect HVAC motors and startup circuits. Otherwise, it’s easy to replace the wrong part and stay stuck.

We’ve seen plenty of “DIY wins” turn into “DIY disasters,” so we try to save people that headache.

ECM Motor Replacement Cost: Why It Can Be Higher

Here’s the part nobody loves.

ECM motors can cost more than PSC motors because:

The motor design is more complex

Many include a control module

Diagnostics can take longer

Some models require OEM parts

Even so, replacing an ECM motor can be worth it. Especially when the system is otherwise in good shape.

Also, if your system is variable-speed, using the correct ECM motor matters. Installing the wrong motor type can cause airflow problems, comfort issues, and control board errors.

How to Protect ECM Motors and Make Them Last Longer

ECM motors can last a long time when the system is cared for.

Here’s what we recommend:

Replace filters regularly

Keep vents and returns open

Schedule annual maintenance

Keep coils clean (dirty coils increase strain)

Address unusual noises early

Don’t ignore weak airflow

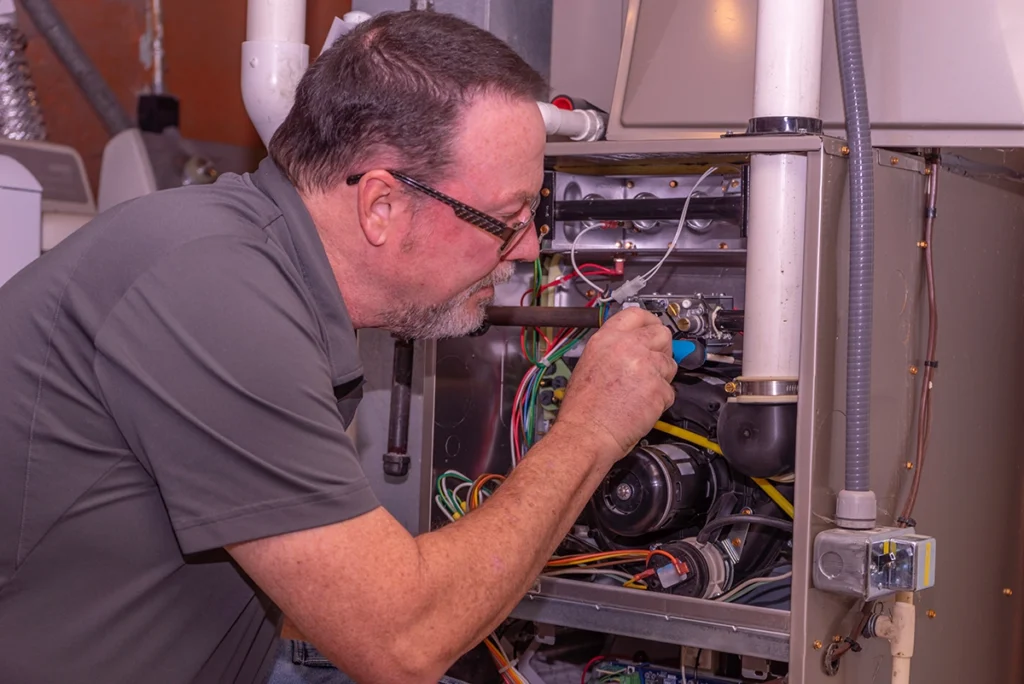

When to Call a Pro

If your blower isn’t coming on, airflow is inconsistent, or the system keeps cycling oddly, it’s time to schedule heating repair with a technician who can test the ECM module and airflow correctly.

Because ECM motors involve electronics, guessing usually gets expensive fast. Proper testing matters. We check:

Voltage and signal inputs

Module response

Motor operation under load

Airflow readings

System static pressure

That’s how you avoid replacing parts “just in case.”

Final Thoughts

At the end of the day, ECM motor technology is excellent for comfort and efficiency. Still, when ECM motors start failing, the symptoms can feel random and frustrating.

If you’re near Vancouver, WA, and your system is showing motor or airflow issues, reach out to Sub Zero Temp Control. We’ll diagnose it correctly, explain the options clearly, and help you get back to reliable comfort. Contact us if you’d like a professional checkup before a small motor issue turns into a bigger system problem.

FAQs

Below are a few quick ECM motor FAQs we get asked often.

An ECM motor is a high-efficiency, electronically controlled motor used for indoor blower airflow.

ECM motors include built-in electronics that control speed and airflow. Because of that, parts and diagnostics usually cost more than older motor designs.

Weak airflow, blower not starting, inconsistent fan speeds, and higher energy bills are common signs.

Sometimes the module can be replaced, but in many cases full replacement is the best fix.What is an ECM motor in HVAC?

Why are ECM motors so expensive?

What are signs of a failing ECM motor?

Can an ECM motor be repaired?